Biomaterials

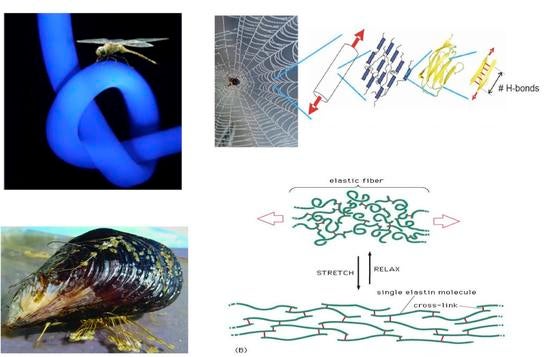

Most of the polymers produced today are exclusively based on petroleum-derived chemicals. Polymer industry will therefore soon face an increase in feedstock cost, a situation currently being experienced by the energy sector. The genetically directed nature of biosynthetic methods offers unparalleled opportunities for the production of polymeric materials, in which structure and function can be precisely specified. For example, spider-silk, mussel byssus, and elastin-like polypeptide have shown promise for the variety of applications as armor fibers, underwater glues and biomedicine carriers. In contrast to chemical polymerization, the cost of producing a compositionally well-defined biopolymer through biosynthesis methods does not increase with increased architectural control and polymer chain length. Moreover, the development of a renewable resource for polymer industry offers positive attributes in terms of green chemistry. As the starting point of this field, we will focus on peptide-based biopolymers and their applications for the production of recombinant proteins. The polypeptide sequences derived from elastin will be computationally designed for in vivo microcompartmentation at desired conditions. These polypeptides will be exploited to improve the yields of bio-pharmaceuticals that are difficult to produce cost-efficiently now. Another application of in vivo partitioning is to engineer a highly efficient bioremediation system for the degradation of toxic pollutants.